The Company

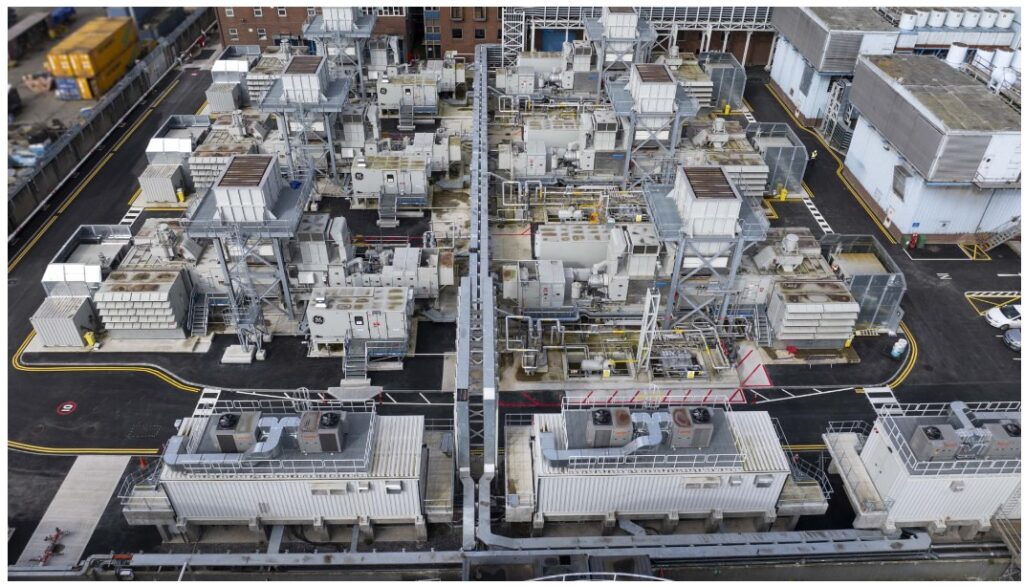

ROTOTECH’s business field is the execution of industrial projects such as power stations, refineries, petrochemical plants, process plants, utility networks and other installations including maintenance, retrofits and repair works.

The experience and the technical background of ROTOTECH’s staff, in combination with company’s organization guarantees the timely completion and the high quality level of the work to be undertaken.

Thanks to our skillful resources and own equipment, we are capable of providing competitive services in the execution of Works with high level of complexity and special requirements to the satisfaction of our customers.

Equipment and tools

Our company owns all the standard tools and equipment for the good performance and the efficient execution of undertaken activities. This equipment is maintained in excellent condition and calibration certificates are kept updated at all times. Special equipment can be mobilized on short term notice.

Our tools and equipment are orderly stored in containerized mobile units which include work benches, shelves & drawers, light machining tools, el. power & lighting installation. These equipment units are very practical, easily forwarded/mobilized on site and occupy less space than other typical storage facilities.

Manpower

Over the last 20 years we have developed trustful relations with the labor markets of Greece, the Balkan countries, India, Egypt and elsewhere. This give us the advantage to mobilize highly qualified resources in sufficient number to promptly and efficiently cover the manpower demands on project’s peak, meet schedule milestones, while achieving high quality standards. The permanent personnel of our company gives us the flexibility and the opportunity to respond on short term Customer’s notices.

Our resources network comprises of highly skilled personnel of the following qualifications:

| • Dipl. or graduate engineers | • Riggers |

| • Experienced foremen and supervisors | • Operators |

| • Mechanical fitters | • Electricians |

| • Pipe fitters | • Instrument fitters |

| • Qualified welders certified for highly alloyed piping | • Insulation fitters |

| • Millwrights | • Semiskilled laborers |

| • Experts for special services |

ROTOTECH provides professional Construction services to the following industrial sectors:

Power stations

- Erection & alignment of gas turbines and their associated equipment

- Erection & alignment of steam turbines and their ancillary plant

- Heat Recovery Steam Generators

- Conventional boilers

- Main Steam Condensers

- Process pumps (FW, condensate, etc), coal pulverizers, fans, blowers and other rotating equipment

BoP installations:

- Piping prefabrication, erection and testing (carbon or stainless steels, medium and high alloys, GRP, HDPE, rubber or cement lined) including Post Weld Heat Treatment

- Water Treatment Plants (desalination, decarbonization, demineralization, condensate polishing)

- Fuel oil storage, treatment and distribution facilities Fuel gas receiving, metering and pressure regulating stations

- Tanks and Pumping Stations

- Sea and river water intake equipment

- Cooling Tower systems

- Fire fighting installations

- Steel structures (buildings, racks, supporting structures, shelters, etc)

Oil refineries

- Installation and alignment of rotating equipment i.e. steam/gas turbines, pumps, compressors, fans, blowers, etc.

- Piping prefabrication, erection and testing

- Furnace and boiler erection

- Vessels and heavy lifts execution

- Towers, reformers and reactors and their internals

- Heat exchangers

Process plants

- Cement factories

- Utility and industrial boilers

- Cogeneration units

- Waste heat boilers

- Waste water treatment plants

- Food processing units

- Dairy products plants

- Incineration plants

- Other industrial facilities

We can cover the full range of construction work i.e. material management, transportation, rigging, assembly, alignment, welding, PWHT, testing, painting, insulation and handing over documentation.

Civil, electrical and I&C works can be executed either by our personnel or by qualified subcontractors depending on the amount of work and project’s demands.

We are capable to provide professional commissioning services to either support Customer’s commissioning organization or to undertake complete pre- or hot commissioning tasks such as:

- Flushing of piping systems (oil, cooling water, fuel oil, gas, etc)

- Chemical cleaning of boilers and water/steam cycle piping

- Steam blowing

- Treatment of chemical cleaning effluents

- Adjustment of valves settings and testing

- Commissioning of rotating equipment

- Commissioning and Start up operations

- Tests and inspections

- Operational services

We can provide other field supporting services such as turnover documentation, supervision and reporting.

Maintenance, retrofit & repair services can be provided in a professional manner to the following industrial sectors:

Machine condition monitoring and predictive maintenance

Our activities in this field aim at machinery condition assessment and fault diagnosis in operation through vibration spectrum analysis. This can be realized either on a regular basis (implementation of a predictive maintenance program), or in specific cases when operation problems arise. Vibration analysis can serve as an independent, as well as a complementary method in order to validate or negate findings obtained by other diagnostic methods such as acoustic emission, oil analysis, infrared thermography, etc. Assets that could benefit from vibration analysis include rotating equipment (i.e. steam/gas turbines, compressors, motors, pumps, blowers, fans, gearboxes, mills, rollers and crushers) but may also include interconnected structures, static equipment and piping, as well. Typical problems that can be detected are unbalance, misalignment, looseness, bent shaft, gear problems, bearing problems, motor internal faults, electrical grounding faults and structural resonances excitation (piping/structural).

- Benefits from implementation of vibration analysis

- • No disturbance in the operation of the equipment or the production program of the plant.(oil, cooling water, fuel oil, gas, etc)

- • Significant reduction of maintenance costs, avoiding unnecessary repairs, spare parts and outages.

- • Smooth and efficient operation of the equipment (lower operational costs)

- • Improve reliability and availability degree of the plant/unit

- How can we help?

-

- Our specialists will define and forecast equipment problems, needs and goals

- We develop equipment operations description complete with drawings, collect real operating data, and generate reports with useful details, trend graphs and exception reports

- We provide specific recommendations, avoiding guess-work

- Perform complete field balancing

- Identify root cause problems

- Propose and apply long term resolutions

- Perform start-up and commissioning acceptance tests

- Complement other condition-monitoring techniques to validate or negate findings

-

We can customize predictive maintenance programs to meet the specific requirements of the equipment/plant/unit. Depending on customer’s needs and decision we are able to realize an optimized maintenance schedule.

Process plants and other industrial installations

We provide professional maintenance, retrofit and repair services at the following technical fields:

• Rotating equipment i.e. pumps, screw feeders, fans, blowers, compressors and mills.

• Conveyors, bucket elevators and other material handling systems

• Boiler retrofits

• Production lines

Applying our Machine condition monitoring and predictive maintenance system, we can assure the smooth, trouble-free and cost effective operation of the plant.

Oil refineries & petrochemical plants

Shutdown and turnaround maintenance and repair services:

- Machine condition monitoring and predictive maintenance through vibration spectrum analysis and other diagnostic methods.

- Field or shop balancing of rotating machinery.

- Maintenance and repairs of steam/gas turbines, pumps, compressors, screw feeders, fans, blowers and other process equipment (i.e. heat exchangers, valves, tanks, vessels, etc).

- Boiler and furnace repairs.

- Repair/reconditioning of reactors and reformers internals

- Heat exchangers re-tubing and tube bundle pulling/pushing.

- Cleaning/de-scaling of plate and tubular type heat exchangers.

- Reconditioning and testing of process and safety valves.

- Lapping of valve seats

- Flanges re-facing

- Post Weld Heat Treatment

- Turnover documentation

Power stations

ROTOTECH provides professional services at the fields listed below, either undertaking completely the agreed scope or supporting the Customer’s OEM’s representatives in a responsible and reliable manner:

- Inspection and tests

- Planned and unplanned maintenance and repair works

- Machine condition monitoring and predictive maintenance

- Other field support services

Our services can be provided either on a frame agreement basis or on a specific case enquiry. If required by our Customer this service may include the provision of:

• Spare and wear parts

• Lubricants and other consumable

In conjunction with the other fields of our activities we can support Customer’s project organization towards the following directions:

- Project and site management

- Planning and progress reporting

- Subcontractors and third parties coordination

- Field supervision

- Estimating

- Lifting studies

- Method statements

- Case studies and assessments

These services are provided in a professional and commercially fair manner, offering added value to Project’s outcome.

ROTOTECH is certified since 2010 to:

- EN ISO-9001 : 2015 for the quality management system

- EN ISO-45001 : 2018 for the occupational health & safety management system

- EN ISO-14001 : 2015 for the environmental management system

- EN ISO-3834-2 as a welding contractor in the product range of industrial steel piping assemblies and single supporting steel structure

Furthermore the “Welding Procedure Qualification Records” (WPQRs per EN/ISO 15614-1-2004 and ASME IX) of the Company cover a wide range of welding procedures for carbon steels, stainless steels and low & high alloy materials.